Euro Slot Punch Machine

Plan IT flow wrap and flow wrapper packaging machines can be customized to match each customer’s specific needs, and deliver maximum production flexibility and efficiency at each performance level. Every model is available in different versions with a large range of optional for the packaging of food and non-food products. We can offer flow wrap packaging solutions from 60 ppm to 500ppm, form manual load to fully automated packaging solutions.

- Euro Slot Punch Machine Embroidery Designs

- Euro Slot Punch Machine Game

- Euro Slot Punch Machine Gun

- Euro Slot Punch Machine For Sale

Flow wrapper packaging machine, the smallest fully electronic flow-pack machine in the world with unique design for vertical and horizontal packaging. Packaging applications includes bakery, vegetables, multipacks such as meal kits and home delivery, snack foods and more. Speed up to 30ppm depending on operator manually loading.

- Voltage : 220V

- Weight : 120 kg (Giulia 350) , 300 kg (Giulia 600)

- Sealing bars opening : max. 120mm (Giulia 350) , 180mm (Giulia 600)

- 2 pairs of longitudinal rollers (diam. 87 mm) : 1 for film tow, 1 for sealing

- Safety carter with auto stop of the machine during production in case of open carter

- Emergency stop buttons for immediate stop of production cycle

- Manual or automatic production modes

- Film reel width : max. 350mm (Giulia 350), 600mm (Giulia 600)

- Film reel holder with locking system

- Loader plates in stainless steel AISI 304 (conforms to CE directives)

- Speed : 30 packs/min

- Easy maintenance and cleaning

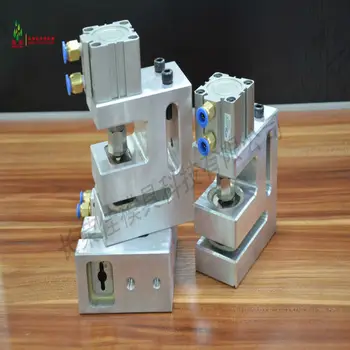

Euro Slot Punch. Closest airport to turning stone casino. Prominent & Leading Manufacturer from Vadodara, we offer Packaging Machine Euro Slot Punch and Pneumatic Euro Slot Punch. Interested in this product?

- 3 axis controlled by servo motors and drives

- Can-Bus communication

- 7” Touch screen display with integrated PLC

- Memory for product’s programs

- Full back up of parameters and product’s programs via USB key

- Product and print centering via touch screen

- Easy diagnose for problem solutions

- Possibility of connection to Team Viewer for remote assistance (LAN , VNC)

- Rotary printer or thermal transfer printer

- Full stainless steel AISI 304 construction

- Euro-slot punch

- Photocell for print centering

- Barrier photocell for automatic detection of product length

Pack 380 Servo Horizontal Flow Wrapper Packaging Machine

Horizontal packaging machine, designed for versatility and for more challenging packaging needs. The Pack 380 flow wrapper is a small, versatile and technologically advanced low-cost packaging machine, aimed at companies looking for a high quality product to optimise their packaging processes. This fully servo packaging machine allows you to save recipe settings on the touch screen and recall within minutes. Pack 380 flow wrapper can package up to 100ppm.

- Voltage: 220 V

- Weight: 320 kg

- Sealing bars: diam. 120 mm

- 2 pairs of longitudinal rollers (diam. 87 mm): 1 for film tow, 1 for sealing

- Safety carter with auto stop of the machine during production in case of open carter

- Motorized exit belt

- Emergency stop buttons for immediate stop of production cycle

- Photocell for print centering

- Film reel width: max. 380 mm

- Film reel holder with locking system

- Loader plates in stainless steel AISI 304 (conforms to CE directives)

- Dimensions: 1800 x 800 x H 1800 mm

- Speed : 80 packs/min

- 3 axis controlled by servo motors and drives

- Can-Bus communication

- 7” Touch screen display with integrated PLC

- Memory for product’s programs

- Full back up of parameters and product’s programs via USB key

- Product and print centering via touch screen

- Easy diagnose for problem solutions

- Possibility of connection to Team Viewer for remote assistance (LAN , VNC)

- Rotary printer or thermal transfer printer

- No product – no bag sensor

- Full stainless steel AISI 304 construction

- Euro-slot punch

- Zig-zag blades

- Fixed forming box

- Extended loader

- Double sealing jaw (to increase productionspeed)

Pack 520 Servo Horizontal Flow Wrapper Packaging Machine

Pack 520 servo flow wrapper is powerful, versatile, technologically advanced packaging machine for companies looking for a high quality product to optimise their packaging processes with a high level of production performance. Pack 520 flow wrapper can package up to 200ppm

It is used ideally for flow wrapping bakery products, but it can also guarantee excellent performance for other types of product, such as snacks, confectionary, meat and frozen products

- Voltage : 220V

- Weight : 800kg

- Sealing bars : diam. 120-150 or 180 mm

- 3 pairs of longitudinal rollers (diam. 120 mm) : 2 for fi lm tow, 1 for sealing

- Opening of all longitudinal rollers via a single lever

- Motorized cut and seal assembly

- Safety carter with auto stop of the machine during production in case of open carter

- Motorized exit belt

- Emergency stop buttons for immediate stop of production cycle

- Additional function buttons on products loader

- Photocell for print centering

- Film reel width : max. 500 or 700 mm (depending on version)

- Pneumatic Film reel holder

- Loader plates in stainless steel AISI 304 (conforms to CE directives)

- Dimensions : 3500 x 1100 x H 1900 mm

- Speed : 150 packs/min

- Cut and seal drive motor : 5 Nm

- Easy maintenance and cleaning

- 3 axis controlled by servo motors and drives

- Can-Bus communication

- 7” Touch screen display with integrated PLC

- Memory for product’s programs

- Full back up of parameters and product’s programs via USB key

- Product and print centering via touch screen

- Easy diagnose for problem solutions

- Possibility of connection to Team Viewer for remote assistance (LAN , VNC)

- Light tower for machine’s status indication

Pack 700 Inverted Servo Horizontal Flow Wrapper Packaging Machine

Pack Inverted is an inverted horizontal flow wrapper featuring either rotary or box motion HFFS technology. The machine is suitable for a wide range of food and non-food products, for both standard and modified atmosphere packaging. In conjunction with MAP barrier films, the machine can deliver high integrity seals suitable for gas flush applications, to extend the shelf life of many food products. Ideal not only for products that require hermetic sealing, but also for difficult-to-handle items or products for the medical industry, meal kits for multipacks, vegetables and etc .

- Voltage : 220V

- Weight : 700kg

- Sealing bars : diam. 120-150 or 180mm

- 3 pairs of longitudinal rollers (diam. 120 mm) : 2 for film tow, 1 for sealing

- Motorized rollers assembly (for up and down motion)

- Safety carter with auto stop of the machine during production in case of open carter

- Motorized exit belt

- Emergency stop buttons for immediate stop of production cycle

- Additional function buttons on products loader

- Photocell for print centering

- Film reel width : max. 600

- Film reel holder with expanding locking system

- Loader plates in stainless steel AISI 304 (conforms to CE directives)

- Dimensions : 4000 x 630 x H 1700mm

- Speed : 120 packs/min

- Easy maintenance and cleaning

- 3 axis controlled by servo motors

- Can-Bus communication

- 7” Touch screen display with integrated PLC

- Memory for product’s programs

- Full back up of parameters and product’s programs via USB key

- Product and print centering via touch screen

- Easy diagnose for problem solutions

- Possibility of connection to Team Viewer for remote assistance (LAN , VNC)

- Light tower for machine’s status indication

- Rotary printer or thermal transfer printer

- Nebulizer for ethyl alcohol

- No product – no bag sensor

- Full stainless steel AISI 304 construction

- Euro-slot punch

- Zig-zag blades

- Fixed forming box

- Extended loader

- Pneumatic opening of longitudinal hot rollers

- Reactive compensation conveyor belt

Designed to be employed in the automatic lines where it differs from its sturdiness, noiselessness and reliability; it finds further application in the standard use, with manual feeding, thanks to its versatility and easy use.

The cantilevered frame and other solutions aimed solving issues linked to the ergonomic and sanitization aspects, allow the use of the Pack 1000 also in advanced applications.

- Performances:

Up to 350 ppm - Product size:

Width: max. 200 mm

Height: max. 120 mm - Reel size:

Up to 500 mm

Outside Ø: max 350 mm

Inside Ø: 70 ÷ 76 mm - Packaging materials:

Heat-sealable

Cold-sealable - Machine weight (net):

1100 Kg abt.

Euro Slot Punch Machine Embroidery Designs

Options

- Automatic splicer

- Photocell for printing registration

- Coder

- Powered feed roll

- Web width 740 mm

- “Long Dwell” sealing head ◊ Easy opening package;

- Outfeed packs control

- Stainless steel version

- No product-no bag

Electrical Features and Management

- Motion control with PLC integrated

- “Touch-screen” operator interface to vary machine parameters, working programmes memorization and machine diagnostic

- Power: 6 Kw

Pneumatic Features

- Compressed air: 6 bar dry and filtered air

- Compressed air consumption

- 20 NL/minute

Automatic feeding equipment provides synchronized flight loading of products onto the wrapper infeed.

Light-Contact Feeding

A light-contact feeder employs servo drives to accumulate product with light backlog pressure and automatically meter incoming products into a flighted conveyor chain.

Non-Contact Feeding

Non-contact feeders are designed for delicate or sticky products and items that cannot be exposed to backlog pressure.

Group Feeding

Grouping feeders accept a random or intermittent supply of product and transforms it into a light-contact or non-contact accumulated backlog of product, suitable for metering to a wrapper infeed. Two, three, and four count per flight are possible.

On-Edge Cookie/Cracker Feeding

The on-edge cookie/cracker feeder feeds stacked cookies or crackers for on-edge wrapping.

The Product Distribution Systems can accommodate a wide variety of products delivered in rows from your processing line, including:

Euro Slot Punch Machine Game

- Breakfast bars

- Candy

- Confectionery

- Crisped rice treats

- Energy bars

- Granola bars

- Nutrition/health bars

- Protein bars

- Soft cakes

- Toaster pastries

The high speed Product Distribution System can be directly integrated to a variety of customer processes including:

To do this use the +/- buttons near the window with a bet line. /quick-hits-slotscom-free.html. In the game there are 30 payment lines therefore in the window of a Bet you can see a size of a final bet on a spin. Features and BonusesThe Hit Platinum has a very simple control unit. So, to start the game you need to set the a size. But the interface of the slot is created by a principle of simplicity and clarity so it’s not difficult to understand with a control unit.

- Cooling tunnels

- Guillotines/slitters

- Ovens

- Spiral freezers

Euro Slot Punch Machine Gun

Tell us about your flow wrapping and automatic feeding system needs

Euro Slot Punch Machine For Sale

Our specialists will help you find the perfect machine for your needs.